Door Hardware for Control Area Fire Rated

past Lori Greene, CSI, AHC/CDC, CCPR, FDAI

Fire doors are an important office of a building'due south passive fire protection system, and doors in a means of egress provide life safety past allowing people to exit quickly when necessary. Nevertheless, the requirements remain a mystery for many architects and specifiers.

Merely put, an opening protective in a fire or fume barrier is required to be a burn down door assembly, which includes the door, frame, hardware, and glazing. These components are not typically required to be supplied by the same manufacturer—in nearly cases, they can be carve up products which are listed, labeled, or classified for use in a fire door assembly. Occasionally, an assembly will exist made of components that have been tested together and must be used to maintain the rating.

This article addresses some of the bones lawmaking requirements pertaining to fire doors, in hopes of making them a little less mysterious. The best way to find the answers is through request the right questions.

Where tin can I notice the code requirements for burn down doors?

National Fire Protection Association (NFPA) 80, Standard for Fire Doors and Other Opening Protectives, is referenced by the International Edifice Lawmaking (IBC), International Fire Code (IFC), NFPA 101, Life Safety Lawmaking, and other codes and standards. NFPA 105, Standard for the Installation of Smoke Door Assemblies and Other Opening Protectives, addresses fume doors and is also referenced in these publications.

Some burn door requirements are included within the applicable edifice or burn down code, but NFPA 80 and 105 are referenced for many of the detailed requirements. For product-specific issues, the manufacturer'southward listings must be referenced. For case, to observe out the maximum burn down door size available from a particular manufacturer, one should consult Underwriters Laboratories' UL Edifice Materials Directory or Intertek's Warnock Hersey Mark Directory.

How can I discover out more about an existing fire door?

Each fire door is labeled with a permanent label that must remain legible. Fire-rated frames may have a label or embossment from a listing agency. The door and frame labels contain a wealth of information, including the manufacturer, length of time the component is designed to resist fire, whether the opening is to be equipped with fire go out hardware, and whether the door carries a temperature rise rating or is a smoke door assembly.

Burn down door labels ordinarily include a number allowing manufacturers to access more than information most the door's original construction. Frame labels may state a fire resistance elapsing longer than that of the door. In this instance, the assembly's rating will be the lower of the two. Some hardware, such as burn exit hardware, will also be labeled, but the information on the label is typically less detailed.

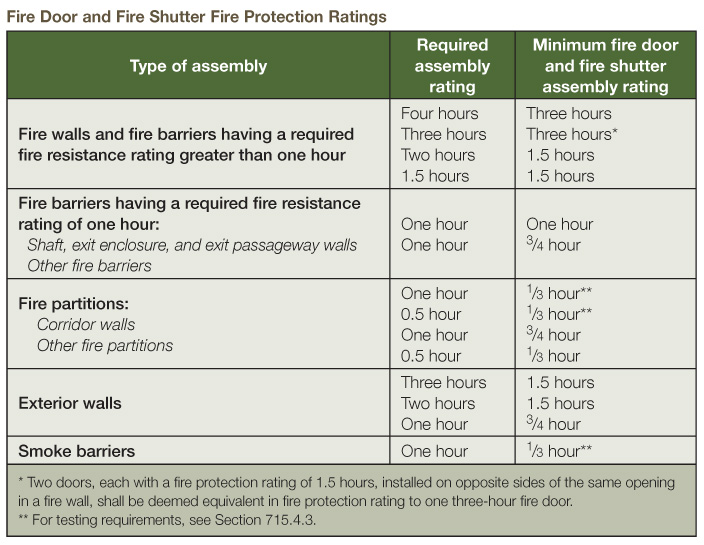

How exercise I know what burn resistance rating I need?

The building code mandates the required fire resistance rating of a wall in a particular location, and too states the required rating of the opening protective, or burn door assembly. The fire resistance requirements for various types of burn walls, fire barriers, and fire partitions, every bit well as fume partitions and fume barriers tin be constitute in Chapter vii of IBC.

The 2012 edition of the International Building Lawmaking includes new tables that assistance clarify the opening protective requirements. For example, Tabular array 716.5 states a two-hour get out enclosure requires a 1 ½-hour fire door assembly, and lists requirements for the drinking glass used in that assembly. The rating of the door assembly is oft less than the required rating of the wall, because it is causeless the door will have a lower fuel load since no combustibles (e.1000. piece of furniture, storage, etc.) volition be piled in front end of the door. If a fire door is no longer needed, information technology should be removed and replaced with construction of the same rating as the wall to arrange the potentially higher fuel load.

When are temperature-rising doors required?

Temperature-rise doors are designed to limit estrus transfer from one side of the door to the other. If there is a fire on one floor of a building, there may be a need to limit the transfer of heat to the other side of the stair door, and so building occupants tin exit safely downwards the stairwell.

The increased use of sprinklers has resulted in reduced requirements for temperature-rise doors. The 2012 IBC requires doors in interior exit stairways/ramps and go out passageways to have a maximum transmitted rise in temperature of 232 C (450 F) above ambient at the end of xxx minutes of exposure, simply also includes an exception stating temperature-rise doors are not required in buildings equipped throughout with an automatic sprinkler organisation.

For the convenience of building occupants, how can fire doors be held open in a code-compliant way?

Burn doors must exist closed during a fire to compartmentalize the edifice and prevent the spread of fume and flames. The intent is to protect the ways of egress and allow edifice occupants time to evacuate safely. If burn down doors are blocked or wedged open up, they will non be able to do their job and protect the edifice and its occupants.

At that place are acceptable ways to hold open burn doors, using electromagnetic holders, or closer/holder combinations that comprise integral smoke detectors or are initiated by the fire warning system. When smoke is detected, the doors close, and provide 20, 45, 60, xc, or 180 minutes of protection. Fire doors are sometimes referred to by a letter designation—A for three hours, B for lx or 90 minutes, and C for 45 minutes (xx-minute doors practise not have a letter). Nonetheless, using the number of minutes is the more common exercise.

A fire door with a standard closer and no concord-open capability is called 'self-closing,' fire doors that close on fire alarm are 'automatic-endmost,' and fire doors with automated operators are called 'power-operated fire doors.' Doors in this terminal category are required past NFPA fourscore to become asunder from ability upon fire alarm, so they are manually operable and cannot be held open up automatically.

What is positive-latching, and is it required for all fire doors?

Hardware on burn down door assemblies has to have an active latchbolt to prevent the pressure caused past a burn down from pushing the door open and allowing smoke and flames to spread. A springlatch found in a standard lockset or latchset is considered an active latchbolt; some burn down door configurations require a specific 'latch throw' (i.e. dimension of latch projection).

A deadbolt is non an active latchbolt, because it can be held retracted. An electromagnetic lock does not provide a positive latch, because in that location is no latching mechanism and the locking is accomplished when the electromagnet bonds to the steel armature. Electric strikes used on fire doors must be fail-secure—that is, when power is cut, the latch is securely captured backside the strike keeper. A fail-safe electrical strike could allow the door to become unlatched, so such strikes may not be used on burn doors.

How is burn down go out hardware different from panic hardware?

When panic hardware is used on fire doors, it must be fire exit hardware, which bears labels for both panic and burn resistance. A door with fire leave hardware will also have an boosted label, indicating it is equipped with fire exit hardware. Fire exit hardware does not contain a mechanical dogging feature—the means to hold the latch retracted using a key, thumbturn, or Allen wrench. For fire doors where a 'push/pull' status is desired, fire exit hardware with electrical latch retraction may be used, equally long every bit the latch projects automatically upon burn down alarm, to secure the door.

Some vertical rod fire exit hardware for pairs of doors can be installed 'less bottom rod' (LBR). These devices use the height rod and latch only, with no lesser rod or latch. The advantage is there is no flooring-mounted strike, and no bottom rod or latch to become damaged by carts or traffic. This configuration tin sometimes cause a reduction in security, considering information technology may exist more easily defeated with only one latching point at the height of the door. In most cases, doors with LBR devices are required to have an auxiliary fire pin, which mounts in the edge of ane door and projects into a pigsty in the edge of the other door if at that place is a burn.

Exercise fire doors need smoke gasketing? Are smoke doors also fire doors?

NFPA fourscore and NFPA 105 practise non specifically country burn doors and fume doors require smoke gasketing. The key is to check the applicable code or standard, such as the International Building Lawmaking, for a limitation on air infiltration, typically a reference to UL 1784, Air Leakage Tests of Door Assemblies, as the test standard.

For fire doors and smoke doors in certain locations, the limit for air infiltration is 0.02 k3/(s • m2) or less equally tested at a pressure level of 0.02 kPa (iii cfm per square foot or less equally tested at a pressure of 0.10 inch of water)—for almost door sizes, this cannot be achieved without fume gasketing. The requirements for fume doors and fire doors depend on where they are used. For example, fume barriers, fume partitions, exit enclosures, and corridors all have varying requirements for smoke and burn down resistance, and the applicable code sections must be consulted to meet if a limit on air infiltration is established.

When does a protection plate on a fire door need to be labeled?

NFPA 80 allows non-labeled kick plates to be field-installed on burn down doors as long as the top of the kick plate is not more than 406 mm (xvi in.) above the bottom of the door. Many door manufacturers have tested with non-labeled plates upwardly to 1219 mm (48 in.) high with no special requirements, merely NFPA 80 currently requires a field-installed plate to be labeled if it extends above the 406-mm marker.

What are the requirements for hinges on a fire door?

NFPA 80 requires hinges and pivots to be steel base material, ball bearing type, and of a certain size, thickness, and quantity depending on the door size, thickness, and fire rating. Ane hinge is required for each 762 mm (thirty in.) of door height or fraction thereof. NFPA lxxx includes criteria for the use of hinges or pivots that practise not meet the requirements listed in the standard, for case, hinges of a dissimilar material, size, or begetting type. Continuous hinges and spring hinges must be tested and labeled for utilise on a fire door.

Although it may be tempting to use spring hinges instead of a door closer on a burn down door for price and aesthetic reasons, it is important to note leap hinges practice not control a door the way a door closer does, and they need to be adjusted to keep them endmost the door over time. In lodge to avert having a fire door that either slams shut or does not close and latch, a door closer may exist better-suited than spring hinges for virtually fire doors.

Can existing fire doors exist modified for new hardware?

Field modifications are limited past NFPA 80 to jobsite grooming for:

- surface-applied hardware;

- function holes for mortise locks;

- holes for labeled viewers;

- protection plates; and

- a maximum 19-mm (¾-in.) forest and composite door undercutting.

Holes drilled in the field are limited to 25-mm (one-in.) diameter, with the exception of cylinder holes that can be any size. For other modifications not specifically addressed past NFPA 80, the list agency may exist contacted through the door/frame manufacturer to request permission to perform a specific modification in the field. Some other option would exist to send the existing doors to an approved facility to modify them, attach new labels, and then reinstall the doors. Burn door assemblies tin also be inspected and relabeled in the field by the listing agency, if acceptable, merely this process tin can exist very costly.

What is 'positive pressure level' with regard to fire door testing?

Positive pressure level testing is a method of testing burn down doors that more accurately simulates the conditions of a real fire than the test that was previously used—UL 10B, Fire Tests of Door Assemblies, also known as a neutral or negative pressure test. The International Building Code requires fire doors to exist tested using the positive pressure test—either UL 10C, Positive Pressure Fire Tests of Door Assemblies, or NFPA 252, Standard Methods of Burn Tests of Door Assemblies, with the neutral pressure level at a maximum of 1016 mm (forty in.) above the sill after v minutes.

The distinction between the two types of tests is peculiarly important with regard to wood doors. To successfully pass the positive pressure test, some wood doors require intumescent fabric—either integral to the door or frame construction or practical subsequently manufacturing. The Window and Door Manufacturers Association (WDMA) describes two types of positive pressure openings:

- Category A doors, which require no additional edge-sealing system (intumescent, if required, is integral to the door or frame); and

- Category B doors, which take practical intumescent material.

A wood door specification should country which type of doors must be furnished for the project.

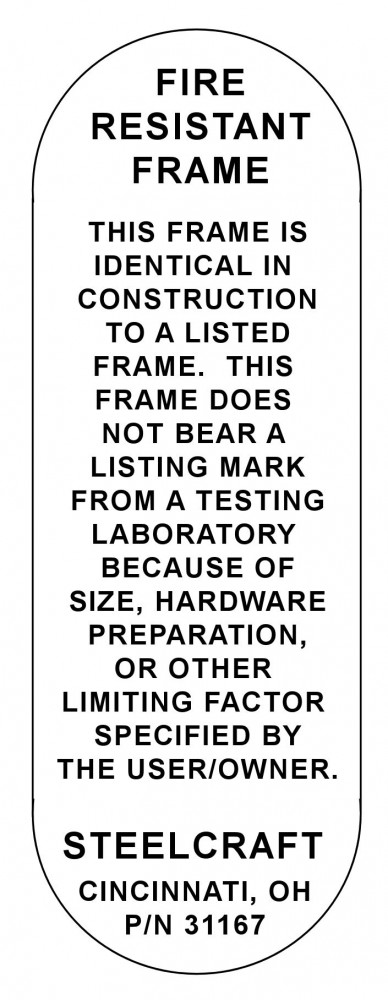

What is a construction characterization and when would information technology be used?

A construction characterization is applied when a door or frame is used in a location that requires a burn down rating, but does not qualify as a rated product. For example, the door or frame may be a size that has non been tested, the jamb depth may be larger (or smaller) than the manufacturer's listings allow, or the specified hardware may not exist included in the manufacturer's listings. This is not the same as a UL or WH/Intertek label, which certifies the product has been tested to withstand fire for the stated menstruation.

The structure characterization typically states the door or frame is identical in structure to a listed door or frame, but does non bear a listing marking from a testing laboratory because of size, hardware grooming, or other limiting factor. The structure characterization does non imply the door or frame is capable of furnishing standard fire protection, simply that it is manufactured with the same materials and methods used in the manufacturers' listings. The label is a means to permanently marker the production so all parties know at a glance the door or frame did not meet the listing requirements. To use a construction label, permission must be granted past the authorisation having jurisdiction (AHJ).

Are annual inspections of fire door assemblies required for all edifice types?

The 2007 edition of NFPA 80 (and all subsequent editions) require fire door assemblies exist inspected each year past someone knowledgeable about the products. A listing of inspection criteria is included in NFPA eighty, and written documentation of the inspection must be kept for review by the AHJ. Deficiencies must be repaired "without delay." This requirement becomes enforceable when a jurisdiction's fire code references an edition of NFPA lxxx published in 2007 or later on. The 2009 and 2012 editions of NFPA 101 too require certain egress doors to be inspected annually.

NFPA eighty has always required fire door assemblies to be properly maintained—the 2007 edition merely added more detailed requirements and included a specific fourth dimension frame. Due to improper modifications and lack of maintenance, the condition of many existing burn doors has rendered them unable to perform in the event of a fire. A burn door blocked open with a forest wedge cannot stop the spread of fume and flames, and damaged latches that have been removed instead of replaced could let the door to be forced open by the pressure of a fire.

Although a jurisdiction may non be officially enforcing the almanac inspection and documentation, fire door assemblies are required to be in good working club. Conducting an inspection and making the necessary repairs tin mitigate the hazard and liability of having fire doors that will not role properly in a fire. Inspecting newly installed fire door assemblies—a requirement of the 2013 edition of NFPA 80—ensures the building owner has a code-compliant installation to begin with, or allows the deficiencies to be repaired during the warranty flow.

Decision

Burn down doors tin can assist compartmentalize a building, prevent the spread of fume and flames, and protect egress routes to allow for rubber escape. Nonetheless, they must be properly specified, installed, and maintained to provide the necessary protection.

Lori Greene, CSI, AHC/CDC, CCPR, FDAI, is the codes and resources manager for Ingersoll Rand Security Technologies. She has been in the manufacture for more than 25 years, and used to be a hardware consultant writing specifications. Greene is a member of CSI, the Door and Hardware Institute (DHI), the International Lawmaking Council (ICC), the National Burn down Protection Clan (NFPA), and the Builders Hardware Manufacturers Association (BHMA) Codes and Government Affairs Committee. She has a monthly cavalcade on code issues in Doors & Hardware, and blogs at www.iDigHardware.com (or www.iHateHardware.com). Greene tin can be contacted via eastward-mail at lori_greene@irco.com.

0 Response to "Door Hardware for Control Area Fire Rated"

Post a Comment